Snapmaker J1s 3D Printer Review Fast Precise IDEX Dual Extruder Innovation

Snapmaker J1s 3D Printer Review Fast Precise IDEX Dual Extruder Innovation

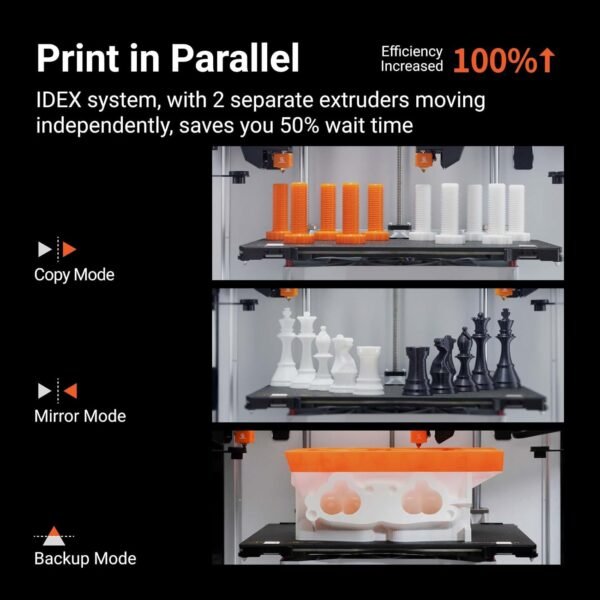

- Dual extruders operate independently, allowing simultaneous printing of two different materials or models without contamination or waste.

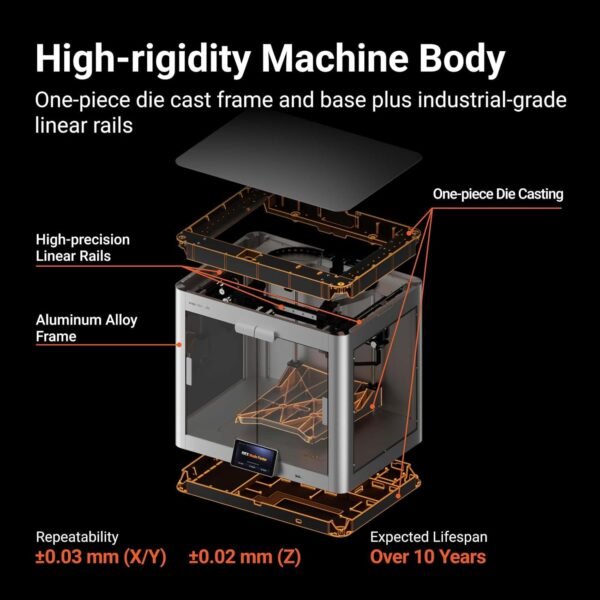

- The rigid one-piece aluminum alloy frame ensures exceptional stability, preventing wobbling and delivering sharp, high-quality prints.

- Vibration compensation technology enables smooth cornering and precise printing, even at high speeds, reducing defects significantly.

- Advanced features like a 300°C nozzle and filament sensor allow for versatile material compatibility and reliable extrusion performance.

As an Amazon Associate I earn from qualifying purchases.

Description

Outstanding Features That Boost Printing Efficiency

Testing the Snapmaker J1s 3D Printer, IDEX 3D Printer 5X Fast Speed revealed some genuinely impressive capabilities. Its independent dual extruder (IDEX) system truly stands out, allowing me to run two prints simultaneously without contamination or waste. This feature alone cuts down my project times significantly, as I can print dual-material objects or two identical pieces in mirror or copy mode. The vibration compensation technology impressed me with its ability to maintain stability during high-frequency movements, ensuring each print has sharp corners and minimal defects. This machine’s one-piece die-cast aluminum alloy housing contributes to its rock-solid frame, which translates directly into precise, wobble-free prints every time.

Positive Features That Enhance User Experience

The more I experimented with this printer, the more I appreciated the advanced extrusion system and its ability to handle a variety of filaments, thanks to a nozzle temperature reaching up to 300°C and smart anti-clogging measures. The inclusion of silicone hot end socks further helps maintain consistent temperatures, which is crucial for producing clean layers. The filament sensor is a handy addition, alerting me before a runout, so no prints were unexpectedly interrupted. The fast and intelligent calibration process, which involves a simplified electrical conductivity method along with a 3-point leveling system, made setup way less stressful. This printer also features double-sided PEI glass plates, enhancing adhesion and reducing first-layer failures dramatically.

- Dual independent extruder system enabling simultaneous prints

- 300°C nozzle temperature and anti-clogging technology

- Quick, 10-minute intelligent calibration system

- Stable, all-metal frame preventing deformation and wobble

Areas for Improvement in the Design and Functionality

While this printer offers a lot, there are certain drawbacks to consider. The weight of the machine—around 48 pounds—makes it less portable and a bit challenging to move around if you’re used to lighter models. The large footprint (about 24 x 20 inches) could be a concern for those with limited workspace, especially since the print volume is quite generous and requires ample room. The price point might feel steep for hobbyists who don’t need dual extrusion or the high precision it delivers. Also, while the cooling system was upgraded in this advanced version, it still gets a bit noisy during intense printing sessions, which can be distracting in quieter environments.

- Heavy and bulky, making transport tricky

- Requires significant desk space due to size

- Noise levels can be distracting during prolonged prints

- Higher price might deter casual users

Print Quality and Material Compatibility

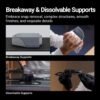

The quality of prints is genuinely impressive. I ran several test prints using PLA, ABS, and PETG, and the results were consistently smooth with excellent detail reproduction. The dual direct drives on the extruders provide better filament control, which is especially noticeable when printing flexible materials like TPU. The cornering optimization technology helps maintain accurate edges and detailed features, which is something I struggled with on other printers. The printer’s ability to pause one extruder without affecting the other is a lifesaver when working on complex dual-material prints; this means I can handle errors or filament changes on one side without scrapping the entire job.

User Interface and Software Experience

Navigating the printer’s controls was fairly straightforward thanks to its intuitive touchscreen interface. The software supports multiple printing modes including single, mirror, copy, and dual-material modes, giving me flexibility for diverse projects. Calibration procedures are guided clearly on the screen, making them less daunting even for newcomers. I appreciated the automatic bed leveling system, which cut down the usual hassle of manual adjustments. However, I did notice that the software ecosystem could benefit from more frequent updates and expanded compatibility with third-party slicers. At times, the learning curve felt a bit steep if you’re not familiar with IDEX technology or advanced 3D printing terminologies.

Competitive Options and How This Printer Measures Up

Comparing this IDEX 3D printer to competitors like the Raise3D Pro2 and Ultimaker S3, it holds its ground well, especially in terms of price-to-feature ratio. The Raise3D offers larger build volumes but at a much higher cost, whereas the Ultimaker excels in ease of use and ecosystem support but lacks independent dual extrusion. The Snapmaker’s vibration compensation and cornering optimization provide a level of print accuracy that’s hard to match in this price segment. On the downside, some competing models have quieter operations and more robust software support. If your projects demand dual-material printing and faster batch outputs, this printer has a clear edge, but for those prioritizing noise levels or extensive brand ecosystems, alternatives might be more suitable.

Value Proposition and Investment Considerations

Considering the price performance of this dual-extruder 3D printer, it offers solid value, especially for those who need advanced features like independent dual extrusion, high-temperature nozzles, and a stable aluminum frame. Its productivity boost through simultaneous printing modes can save significant time in professional or educational settings. However, if you’re a beginner or only dabble in simple prints, the investment might not be justified given the learning curve and size. The machine’s build quality and print precision justify the price for enthusiasts and prosumers who want to push their creative boundaries. Overall, it feels like a smart spending choice for users who maximize those advanced functionalities.

Final Thoughts on Operation and Maintenance

Operating the printer daily, I noticed that maintenance is relatively straightforward. The silicone socks on the hot ends simplify cleaning and protect against jam buildup, while the filament sensor helps avoid mid-print surprises. The ease of replacing parts like nozzles and PEI sheets means I spend less downtime tinkering. Still, the printer’s weight and size require a dedicated space, and if you’re moving it around often, it might become a hassle. The noise level, while not unbearable, is something to keep in mind if your workspace is in a quiet area. Overall, it blends robust build quality with thoughtful features that make everyday printing less of a chore.

This review reflects my hands-on experience with the Snapmaker J1s 3D Printer, capturing both its impressive strengths and areas where it could improve. It’s a versatile, precise machine designed for users who want to expand their 3D printing capabilities with dual-material projects and faster production cycles.

Additional information

| Product Dimensions | 24.41 x 20.08 x 21.26 inches |

|---|---|

| Item Weight | 48.4 pounds |

| Item model number | J1 |

| Date First Available | October 13, 2021 |

| Manufacturer | Snapmaker |

| Country of Origin | China |